Wire Rope Selection

By Colin Rice

Wire ropes are designed to run through sheaves but sheave wheel diameter has a significant impact on the strength efficiency of the rope.

This is the third article of Part 1 of our Technical Series on Wire Rope. Click here for an outline of the entire Technical Series on Wire Rope.

Hoists and winches on drill rigs have multiple layers of rope that spool haphazardly onto the drum and so significant damage can be caused to the rope at an accelerated pace if the incorrect design of rope is used and the rope is not correctly cared for. It is very important that all wire ropes used on drill rigs are carefully selected based on the winch and sheave wheel design. If the sheave wheel is very small then a more flexible fibre core rope would be best suited but if the sheave is large then a less flexible but stronger iwrc rope can be used.

The effect of sheave wheel diameter on working load

In the previous article, we discussed how a wire rope fatigues due to cyclic stress reversals as the rope moves over a sheave. Exactly the same happens when a rope spools off of and onto a hoist or winch drum. The smaller the diameter of the sheave or the hoist drum, the greater the amplitude of the stress reversal will be and so the more rapidly the rope will fatigue.

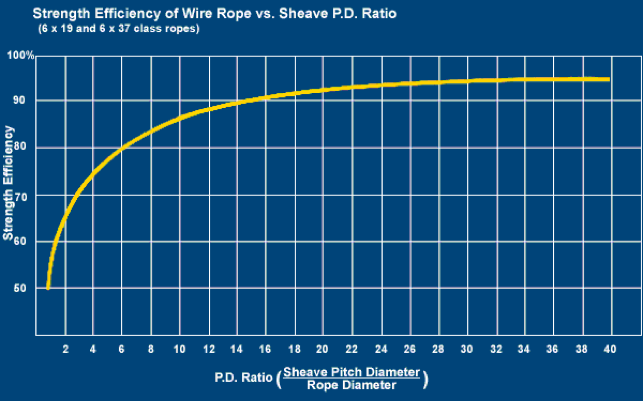

The practical effect of this is that we need to “de-rate” the safe working load of the rope by a factor depending upon the relationship between the diameter of the sheave and the diameter of the rope. This is called the “PD ratio” and is the diameter of the sheave divided by the diameter of the rope.

Figure 1: Strength efficiency of wire ropes versus PD ratio

For example: If the diameter of a sheave is 206 mm and a 16mm rope (SWL = 4MT) runs over the sheave, then the PD ratio is 12,8 (206 divided by 16).

For each construction of rope, it is possible to obtain a strength efficiency graph that shows the relationship between the strength efficiency of the rope and PD ratio. Figure 1 is such a graph for 6 x 19 and 6 x 37 ropes.

In the example used above, a PD ratio of 12,8 translates into a strength efficiency of approximately 88% - this means that the safe working load of the rope must be de rated to 88% of 4MT = 3,52MT.

It is obviously desirable therefore to design drill rigs with as large a sheave wheel as practically possible so that the de-rating effect is minimised.

Figure 2 shows an Atlas Copco CS 14 drill and a Boart Longyear LF 90 drill, both drills use 16mm hoist rope. The CS14 has a single sheave of approximately 600 mm diameter while the LF90 drill uses a pair of sheaves that are approximately 220 mm in diameter.

The PD ratio for the CS drill is therefore 38 and for the LF drill is approximately 14. Figure 2 tells us that the Safe Working Load of the rope on the CS drill must be de-rated to 95 % and the LF drill to 90%.

Figure 2: Atlas Copco CS 14 drill and a Longyear LF90 Drill. Note the difference in sheave wheel diameter.

The next article in the Wire Rope Series focuses on wire rope terminations.