DrillSafe was recently part of the GSSA Geoskills day.

Read MoreWe recently linked up with the Australian Drilling Industry Association, read more here.

Read MoreA failed air hose recoils at substantial velocity and force. In this article we estimate the force exerted by the failed air hose.

Read MoreIt is essential that hose socks have sufficient strength to withstand the very large forces that are exerted when an air hose or fitting fails. In this article, we examine the factors of safety of hose socks.

Read MoreTo be effective, hose socks must be correctly sized and fitted. In this article, we discuss a simple way to ensure that the sock is correctly sized.

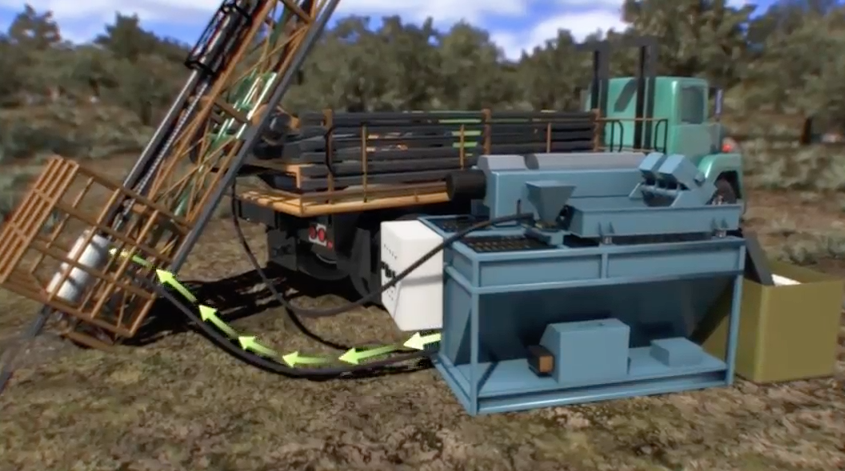

Read MoreSolids control is a critically important part of a diamond drilling operation. In this article, we discuss how poor solids control can lead to in-hole problems.

Read MoreSRUs are being used more frequently in diamond drilling operations. What is an SRU?

Read MoreA video by American Iron Works detailing the correct fitting procedure of hose socks.

Read MoreAn informative video that outlines how an SRU works and the many benefits that they offer to a drilling operation.

Read MoreCompressors and boosters are an indispensable part of the drilling industry. Compressed air is used to drive downhole hammers and is typically reticulated through flexible hoses to operate some sort of hand held tool.

Read MoreWritten by Ian Speer - read more about some of the safety issues you could face and how to address them.

Read MoreWritten by Ian Speer - read about some of the safest ways to achieve lowest hose costs while minimising the operating risks to personnel, plant and the environment.

Read MoreAre we using the term 'biodegradable' too loosely? This article investigates if we should be using different terminology.

Read MoreThe Material Safety Data Sheet is an essential document for both contractors and mining companies. It's a good idea to ensure your supplier can explain it to you.

Read MoreHere are some practical points to assist in building a risk mitigation plan.

Read MoreRead about the legal obligations and implications of drilling fluids and foams.

Read MoreA well designed drilling fluid is an indispensable part of any drilling operation however, circulating mixtures of chemicals through a borehole introduces a series of risks some of which are more difficult to manage than others.

Read MoreHigh pressure air is a potentially lethal hazard - read about the most effective restraints.

Read MoreThis hazard alert is part of our Technical Series on Compressor and Air Hose Safety. Click here for an outline of the entire Compressor and Air Hose Safety Series. Other hazard alerts can be viewed here.

Read More